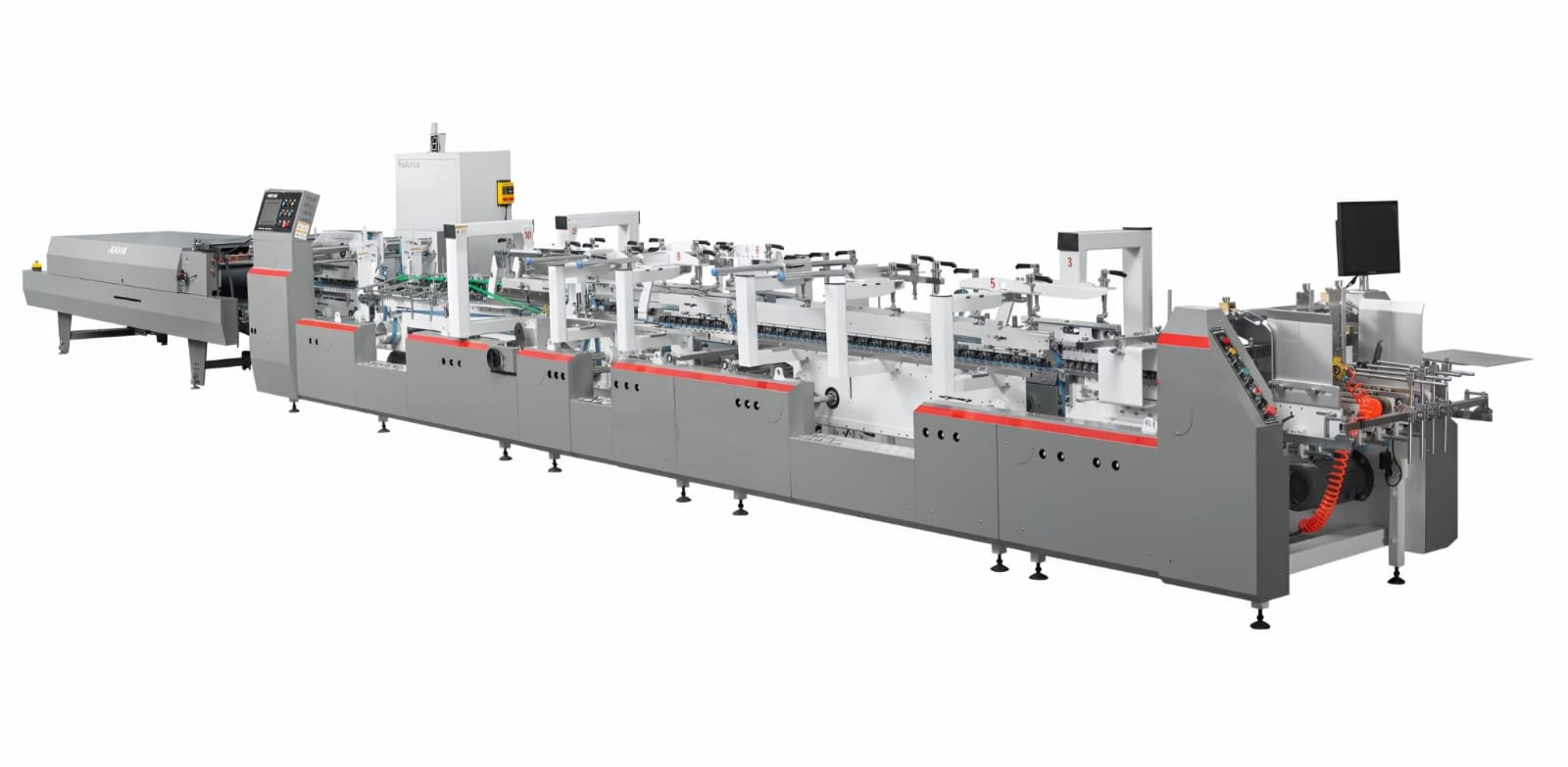

5 Ply Flute Laminator Machinet

Automatic high speed 5ply servo flute laminating machine is a new generation of high-speed laminating machine developed by our company. It can laminating three sheets of card board at once, and can produce three-layer, four layer, five layer, seven layer, and nine layer boards to increase material strength and thickness. The bottom paper adopts a lead edge feeding structure for stable paper feeding, and the servo tracking and correction principle of the top paper. Can achieve a maximum laminating speed of 160 meters/minute. High speed, efficiency, and precision are your ideal choices.

PERFORMANCE CHARACTERISTICS

1. This machine can laminate combination of two corrugated boards and any type of top sheet together. It can produce two -layer board (cardboard + cardboard), 3ply, 4ply, 5ply, 7ply and other products.

2. Total 11 servos. Keep the machine steady and run with high speed.

3.Laminating type: corrugated + corrugated + cardboard, corrugated+ corrugated, corrugated + cardboard, cardboard + cardboard, cardboard + gray board +cardboard, etc.

4. Bottom paper feeding structure adopts a lead edge feeding, an extended and widened belt with large suction to ensure stable bottom paper and cardboard feeding without damaging the cardboard.

5. The host adopts a large roller (160mm) design for stable operation and high efficiency. The stainless steel mesh roller of the large roller (160mm) is evenly coated with glue, saving glue amount, and does not throw glue.

6. The surface of the laminating roller and pressing roller is made of special polyethylene material, and the glue automatically falls off and is free from wiping.

7. Adopting a dual servo top paper correction structure, the top paper and bottom paper(cardboard) are automatically detected and servo corrected, ensuring high precision in tracking and adhering to the front gauge of the top paper and bottom paper (cardboard).The front gauge can be adjusted independently according to product needs.

8. There are two types of paper feeding structures for the top paper lifting platform, pre-stacking paper structure and non pre-stacking paper lifting platform.

9. The bottom paper pressurization device improves the stability of paper feeding for warped paperboard, and the multifunctional paper tray in the bottom paper stacking section is suitable for warped paperboard.

10. The main engine bearings are automatically lubricated at regular intervals, ensuring smooth operation and extending the lifespan of the equipment.

11. Adopting a reflux glue system to reduce glue loss and stabilize glue adhesion effect.

12. One -click adjustment of the whole machine (just enter the paper size).

Related Products

Automatic folder gluer machine

Learn more

High Speed 3Ply Flute Laminator Machine

Learn more

Film Lamination Machine

Learn more

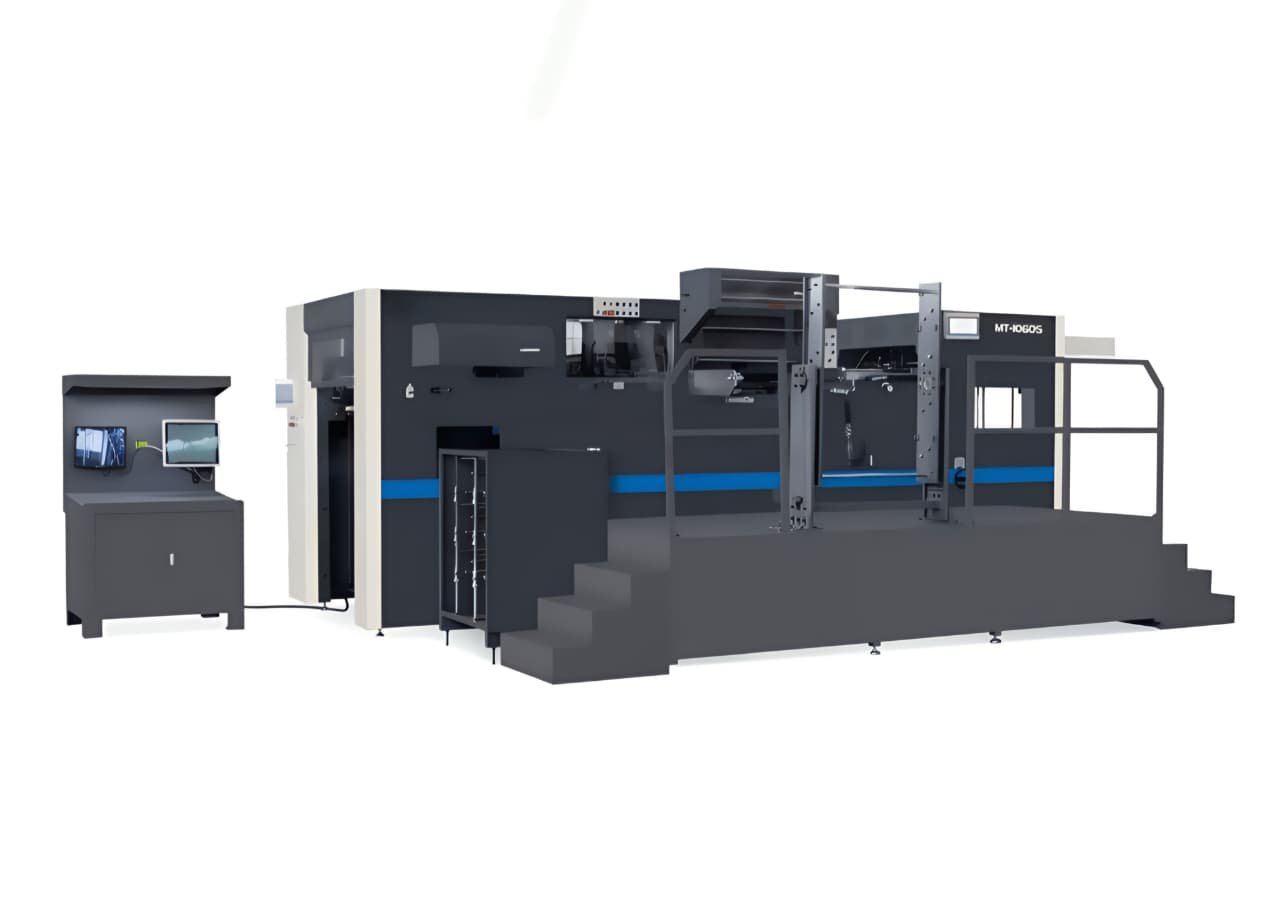

MT 1080 Automatic Die Cutting Machine With Foiling.

Learn more

Automatic Flute Laminator Machine

Learn moreGet in touch

You will find yourself working in a true partnership that results in an incredible experience, and an end product that is the best.

Call us on

+91-8630165313

Email us

kpmachineryandservices@gmail.com