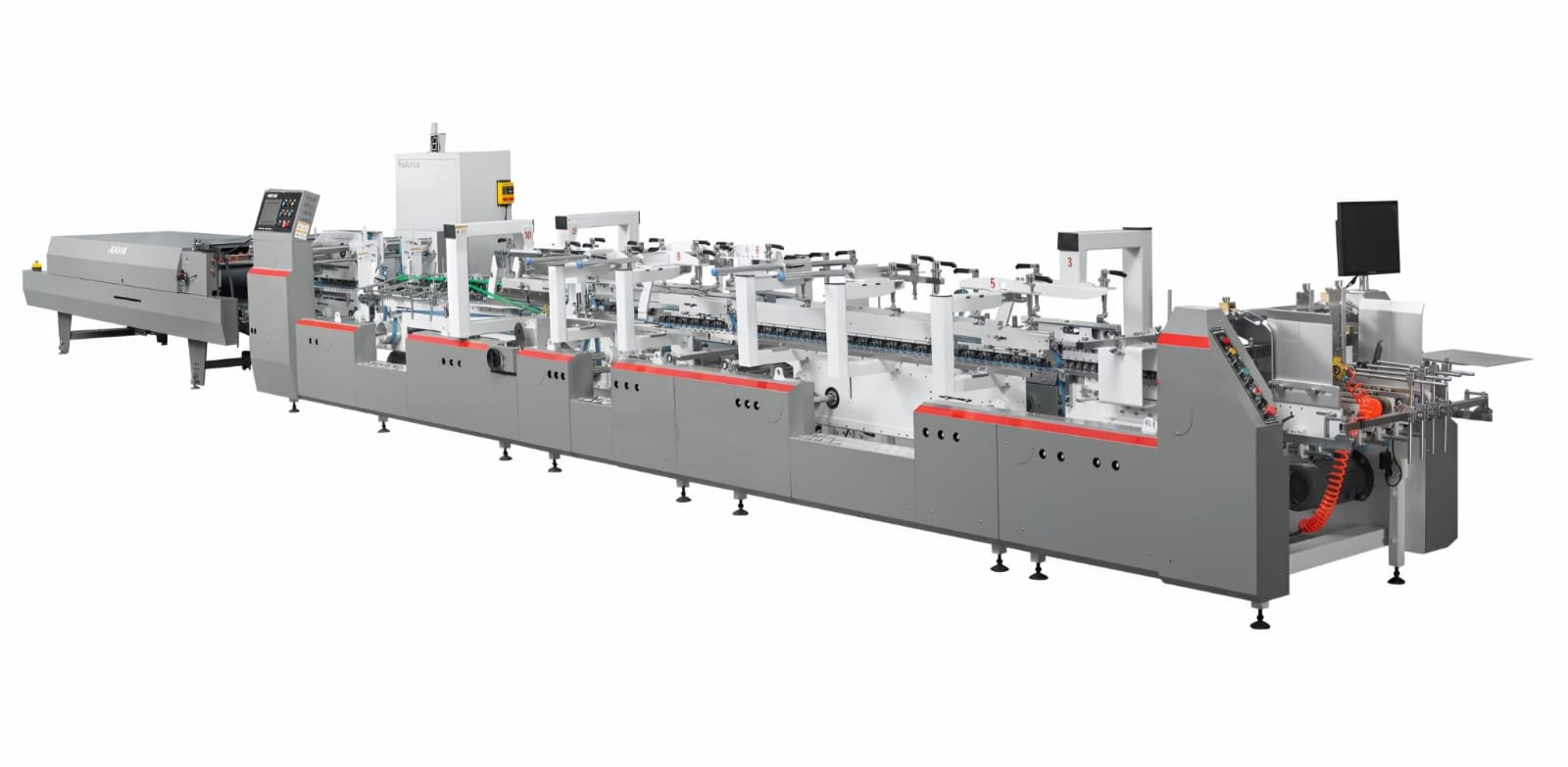

Film Lamination Machinet

1.Automatic Feeder: Adopts offset feeder with advanced pneumatic side lay, which fastest can feed around 13000 sheet/h. Non-stop and pre-stack feeding can improve work efficiency.

2.Overlapping Regulator: Adopts Servo system to control the overlapping that guarantee accurate and stable, and make sure the overlop error within 2mm.

3. Drying and Heating System: 600mm diameter drying roll, that could bring the highest glue drying effect, Large heating roll by oil heating, guarantee the heatingefficiency and make sure laminating quality when run in high speed.

4.Main Machine Body: Thicken machine wall (25mm thickness) enhances stability and for long time service life.

5. Two Rows Chain Driving System with Gear box: Special structure design in minimum transmission line , adopts two rows chain with gear box to drive the laminating unit to guarantee the high laminating speed with low noise.

6.Hydraulic Pressure System: The machine adopts hydraulic system to control the laminating pressure, the pressure would highly uniform and easy to adjust.

7.Man-Machine Interface System: Advanced 10inch color screen with PLC system make the operation easy and convenient.

8.Flying Knife: Adopts imported ultrasonic probe with German chain, servo control system with high accuracy.

9. Anti-Curvature Device: Avoid paper curvature and make the paper smooth, especially for thin paper.

10. Corrugated Delivery: Better and easier for collecting paper.

11 Car Body: Whole machine cover adopts car body, glossy and wear-resisting.

12 Automatic Stacker: Full automatic with sensor to rise and down the paper pile, heightenstructure that can load paper pile height in 1060mm, side and front tidy devices to make sure paper pile collect well.

Related Products

Automatic folder gluer machine

Learn more

High Speed 3Ply Flute Laminator Machine

Learn more

5 Ply Flute Laminator Machine

Learn more

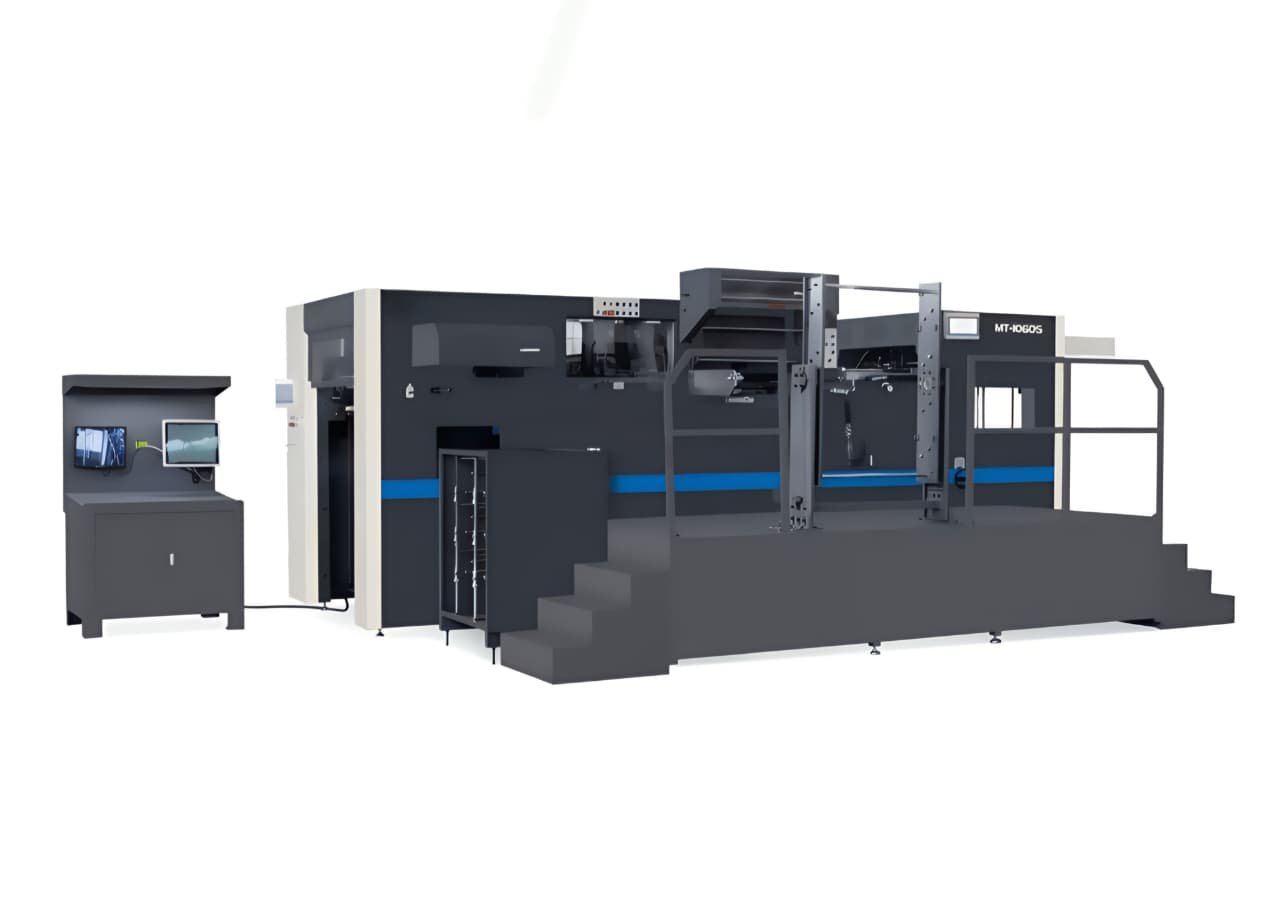

MT 1080 Automatic Die Cutting Machine With Foiling.

Learn more

Automatic Flute Laminator Machine

Learn moreGet in touch

You will find yourself working in a true partnership that results in an incredible experience, and an end product that is the best.

Call us on

+91-8630165313

Email us

kpmachineryandservices@gmail.com