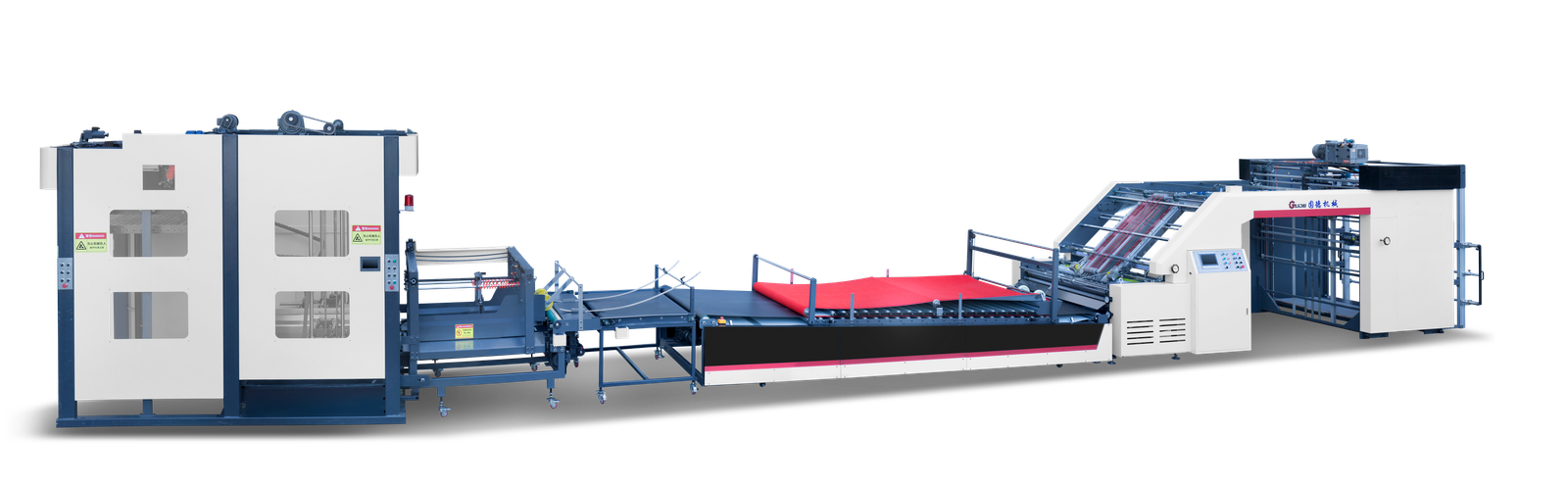

QMY-1050P Full Stripping Die Cutting Machinet

I. Product introduction

QMY-1050PAutomatic die cutting machine with completely stripping is my company after many years engaged in automatic flat bed die cutting machine design, production and manufacturing experience, comprehensive the advantages and disadvantages of domestic and foreign main stripping equipment and customer needs, innovation and development of a new generation of complete stripping die cutting indentation machine with the function of secondary stripping mechanism. Weare stable, durable, safe, easy to operate the design idea for the development of the model of the dominant idea, follow the European Union CE safety certification standards, the overall frame structure of the machine and most of the main institutions to do significant innovation, the safety protection has been carefully improved, so the machine performance is more stable, more safe and convenient operation. The equipment can be applied to die cutting of most materials of paper products printing and packaging enterprises, such as 80-1200 g of cardboard, self-adhesive, 4mmbelow corrugated board, color pitting paper, PET, PVC, PP and other materials of die cutting, concave and convex, embossing and other processes, and at the same time, Using the waste discharge function of this machine to clear the holes, special-shaped corners and other waste edges except the bite edge, greatly reduce the labor cost and labor intensity of the unpacking workers, improve the cleanliness of the production workshop, increase the recognition of customers in the printing order. The machine adopts feeder superior and exquisite design, can be stable and accurate paper feeding paper, one suction, two suction height and angle can be adjusted separately, and equipped with paper preparation trolley, greatly improve the yield and efficiency, the main and auxiliary paper holder automatic exchange, easy to operate. In order to meet the high positioning accuracy of the machine, the side positioning push-pull device and high precision intermittent divider are all made in Taiwan. The main engine adopts the crankshaft movement mechanism to withstand heavy load design, stable pressure, high precision, wear-resisting is not easy to lose, pneumatic lock version device is convenient and fast. The action of the three-frame connected stripping device is stable, accurate and powerful. The upper and lower grinding tools of double-layer drawer stripping can be loaded and unloaded quickly and the stripping tools can be adjusted. It can be assembled according to the die - cut products, convenient and fast loading and unloading, and it has a secondary waste discharge system. Electrical appliances are mostly used in Europe, Japan famous brand original devices, in order to improve the quality of control; Advanced PLC programmable controller systemics adopted, the circuit control program is simple, easy maintenance, the whole working process of electric eye monitoring with large-capacity man-machine interface LCD screen, and provide detailed fault causes and elimination methods, and indicate the equipment daily maintenance precautions.

II. Technical parameters

| 1. Maximum paper size: | 1050x740mm |

| 2. Minimum paper size: | 400x360mm |

| 3. Maximum die cutting size: | 1040x730mm |

| 4. Maximum die cutting pressure: | 80-1200g /m²(corrugated thickness <5mm) |

| 5. Max pressure | 300T |

| 6. Gripper Margin | 8mm |

| 7. Maximum die cutting speed: | 8000sheets/h |

| 8. Total power of machinery: | AC380V three-phase 50HZ |

| 9. Power requirements: | 23KW |

| 10. Total weight of machinery: | 18T |

| 11. Maximum mechanical speed: | 8000 sheets/h |

| 12. Machine dimensions: | 7020x4050x2030mm |

III. Standard configuration and function

Related Products

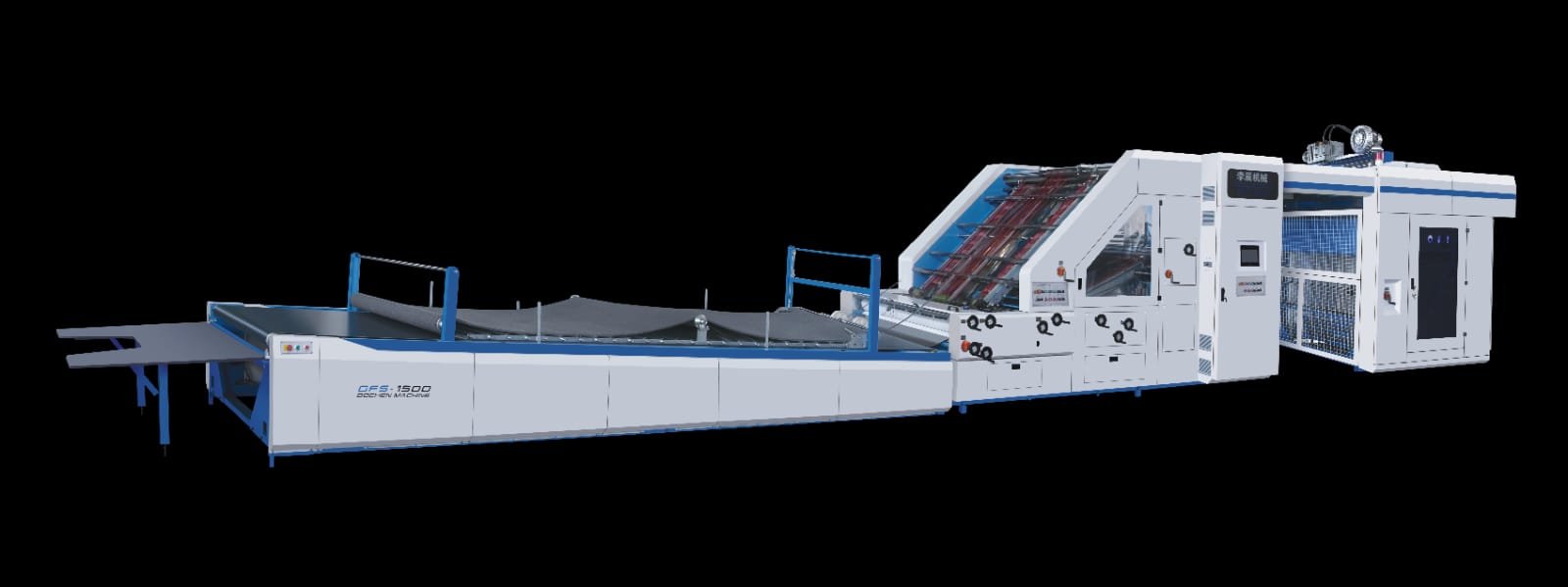

High Speed Flute Laminator Machine

Learn more

Film Lamination Machine

Learn more

5 Ply Flute Laminator Machine

Learn moreGet in touch

You will find yourself working in a true partnership that results in an incredible experience, and an end product that is the best.

Call us on

+91-8630165313

Email us

kpmachinery@gmail.com